Biotechnologists have been improving processes for growing living tissues in vitro (outside the body, in the lab) for many years. Several organisations are now developing ‘biofabricated’ (or ‘bioprinted’) products using these techniques, such as in vitro liver and skin culturing for medical procedures, slaughter free meat and, in this case, leather.

The claimed benefit over existing ‘fake’ leathers is that it is almost the same tissue and structure as real animal leather so has similar properties and performance. The claimed benefits over both fake leather which is usually made of petroleum products, and animal leather, are ethical considerations and sustainability. A study found that cultured meat could use 99% less land, 96% less water, 45% less energy and with 96% less greenhouse gas production than conventional animal farming, for example.

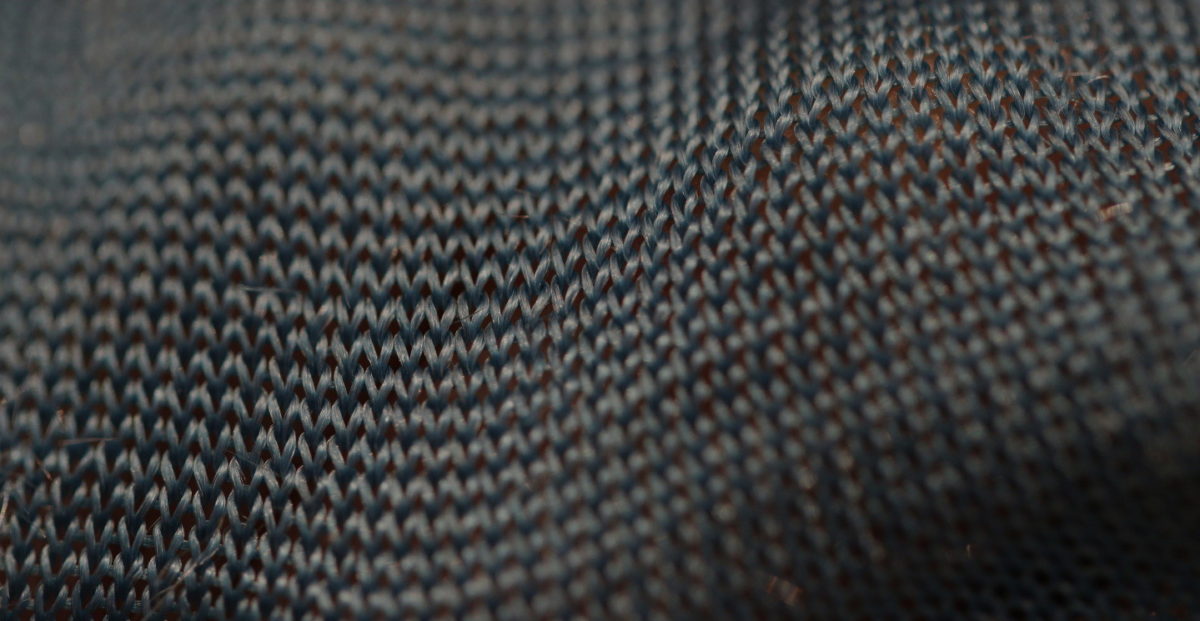

Startup Modern Meadow is pioneering with it’s first product ‘Zoa‘ (swatches pictured above and T-Shirt using it pictured below) a ‘bioleather’ that is “designed and grown from animal free collagen, which can be combined with other natural or manmade materials offering new aesthetic and performance properties.” Unlike animal grown leather, the material is “able to be any density,” “hold to any mold” and “take on any texture”, with genetic engineering potentially widening the range of properties even further. See founder Andras Forgacs’ TEDx talk.

Other pioneers include VitroLabs (incubated at Future Tech Lab; “a disruptive movement of innovators bridging together fashion and science to create a sustainable future.”) which uses stem-cell technology and tissue engineering to create ethical leather from cow, ostrich and crocodile cells.

Note that the technology is in its infancy, so large ranges of refined products and production-scale supply chains are not yet established.

Uses

- Fashion: the Zoa-leather detailed T-shirt pictured above, and exhibited at MOMA is the only finished product we have found, and not for sale as far as we know.

Potential Uses

- Anywhere that conventional leather is used; clothing, accessories, furniture etc.

- If properties and sizes are developed beyond those available in conventional leather then new use cases may arise; building facades / roofs? tents? aeroplane ‘skin’? bedding? lorry tarpaulins? curtains? room dividers? geo-textiles?…

- Any other ideas or exploratory projects you are aware of please do comment below.

Process

- Source cells: currently harmless ‘punch biopsies’ (cylindrical cores of skin tissue removed with a small circular blade) are taken from living donor animals such as livestock or exotic animals.

- Isolate cells, and potentially make beneficial genetic modifications.

- Grow the millions of extracted cells into many billions in a bioreactor or other growth apparatus.

- Centrifuge (spin quickly) the products to remove the growth medium and clump the cells together.

- Bioassembly: put the cell clumps together into layers and allow them to fuse. A number of techniques could potentially be used, including ‘3D bioprinting’.

- Mature the fused cells in a bioreactor for several weeks to stimulate collagen production.

- Stop food supply to the cells, causing the ‘skin’ tissue to turn to hide.

- As the hides do not have hair or tough outer skin, a simpler than usual tanning process is used that decreases the amount of chemicals needed.