Thin slices of bamboo stalk are carbonized, weaved and compressed to produce a composite which has three times the density of natural bamboo, resists moisture absorption, swelling, and decay from bacteria and fungi. The carbonisation processes is effective at eliminating all natural sugars in the bamboo material and therefore becoming unattractive for fungi and bacteria.

Uses

A common use is for flooring providing a more resistant and faster growing alternative to hardwood flooring.

Potential Uses

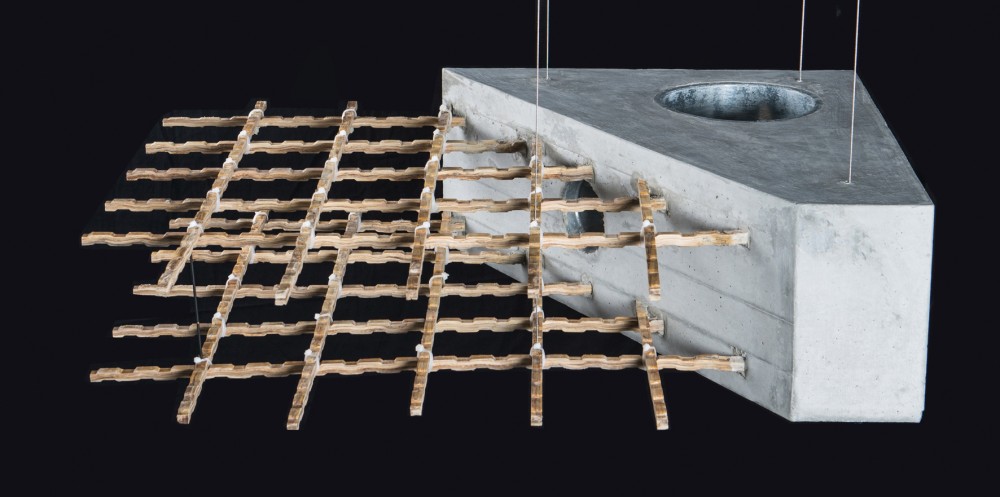

WSB is also being explored as a rebar (reinforced concrete) alternative to replace steel. One such bamboo known as Dirk Hebel Bamboo is being tested by researchers (led by Dirk Hebel) at the Future Cities Laboratory in Singapore. The results have been positive however research continues on an alternative WSB manufacturing process that reduces potential damage to bamboo fibres caused by carbonisation.

Processes

More Information

- https://www.ambientbp.com/how-bamboo-flooring-is-manufactured.php

- http://www.architectmagazine.com/technology/two-natural-rebar-alternatives-for-concrete_o